Fire Barrier Caulk Fire Sealant – INSS1440

INSS1440 Fire Barrier Caulk – Technical Data Sheet

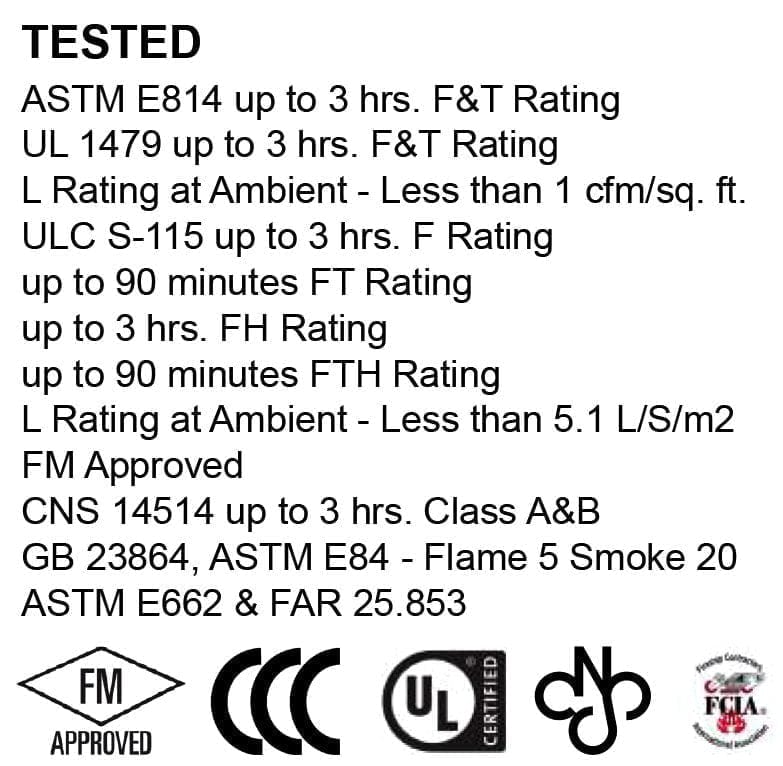

FM Approval Certificate of Compliance

INTERTEK Approval Certificate of Compliance

UL Approval Certificate of Compliance

Industry leading Firestop Technology, INSS1440 Fire Barrier Caulk Fire Sealant is a single component water-based acrylic intumescent firestop sealant.

INSS1440 Fire Barrier Caulk Fire Sealant Listed designs use less product and offer exceptional performance, making it more cost effective than other traditional firestop caulking’s. The product’s fast expansion technology quickly fills voids, offering excellent protection from fire, heat transfer, smoke and gases.

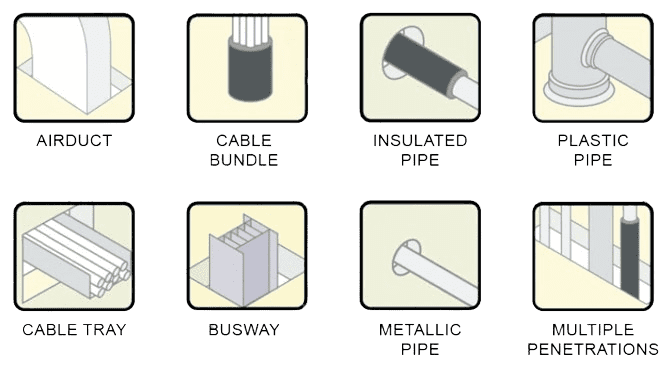

INSS1440 Fire Barrier Caulk Fire Sealant is used for sealing gaps around single or multiple penetrations through interior walls and floors, or for sealing gaps around doors and window frames in critically fire rated structures. INSS1440 Fire Barrier Caulk will adhere to most construction materials and penetrant items, is installation friendly, asbestos and halogen free, and can be painted after full curing.

1.Ensure application area is clean and free of oil, loose dirt, rust or scale and is dry and frost free.

2. Install the correct depth and compression of backing material, if required, as detailed within the applicable listed system, allowing for sufficient depth of fill material.

3. Using a caulking gun, trowel or putty knife, apply INSS1440 fire barrier caulk into the seams, gaps or voids between forming material and floor or wall surface.

4. Tool the sealant surface smooth using a putty knife dipped in water, making complete contact with substrates to ensure an air and smoke tight seal.

5. Clean up, as necessary, with water.

6. INSS1440 fire barrier caulk cures by water evaporation and is not recommended for use in a wet environment.

Specific Density: 1.50 ± 0.1 g/cm3

Color: Gray

Tack Free time: 30 minutes

Curing time: 7 – 21 days

Expansion rate: 3 – 5 times

Application temperature: 40° F – 104° F (5° C – 40° C)

In-Service Temperature: -13° F – 176° F (-25° C – 80°

C) Storage Temperature: 50° F – 95° F (10° C – 35° C)

Packaging: 310 ml/Tube, 25/CTN;

600 ml/Sausage, 20/CTN; 1 gal/pail & 5 gal/pail

Shelf Life: 24 months

Performance: 50+ years HOAC tested

Fire Barrier Caulk Fire Sealant – INSS1440

INSS1440 Fire Barrier Caulk – Technical Data Sheet

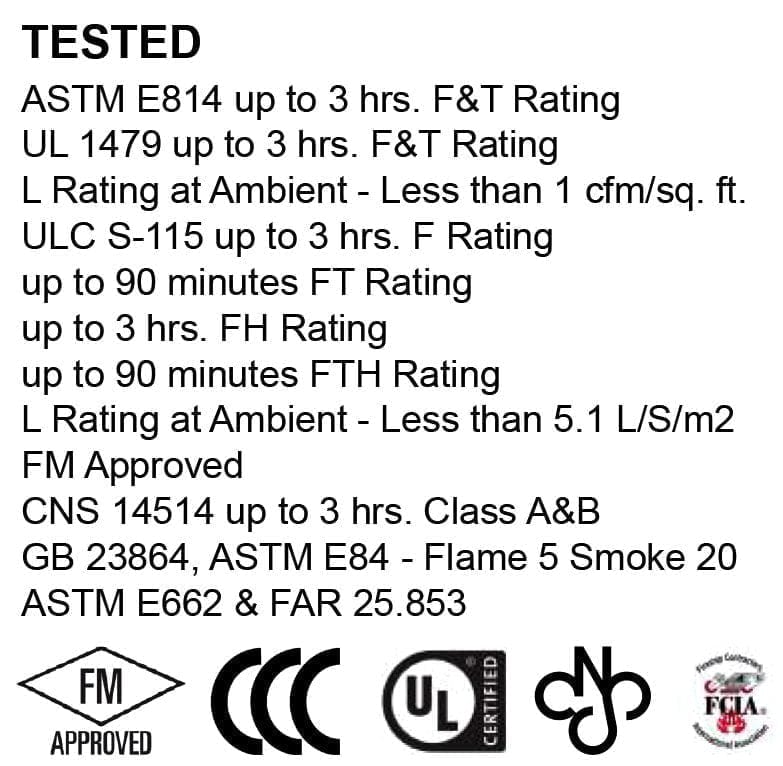

FM Approval Certificate of Compliance

INTERTEK Approval Certificate of Compliance

UL Approval Certificate of Compliance

Industry leading Firestop Technology, INSS1440 Fire Barrier Caulk Fire Sealant is a single component water-based acrylic intumescent firestop sealant.

INSS1440 Fire Barrier Caulk Fire Sealant Listed designs use less product and offer exceptional performance, making it more cost effective than other traditional firestop caulking’s. The product’s fast expansion technology quickly fills voids, offering excellent protection from fire, heat transfer, smoke and gases.

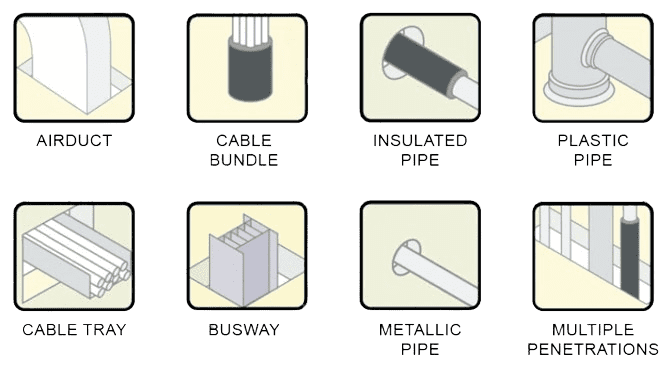

INSS1440 Fire Barrier Caulk Fire Sealant is used for sealing gaps around single or multiple penetrations through interior walls and floors, or for sealing gaps around doors and window frames in critically fire rated structures. INSS1440 Fire Barrier Caulk will adhere to most construction materials and penetrant items, is installation friendly, asbestos and halogen free, and can be painted after full curing.

1.Ensure application area is clean and free of oil, loose dirt, rust or scale and is dry and frost free.

2. Install the correct depth and compression of backing material, if required, as detailed within the applicable listed system, allowing for sufficient depth of fill material.

3. Using a caulking gun, trowel or putty knife, apply INSS1440 fire barrier caulk into the seams, gaps or voids between forming material and floor or wall surface.

4. Tool the sealant surface smooth using a putty knife dipped in water, making complete contact with substrates to ensure an air and smoke tight seal.

5. Clean up, as necessary, with water.

6. INSS1440 fire barrier caulk cures by water evaporation and is not recommended for use in a wet environment.

Specific Density: 1.50 ± 0.1 g/cm3

Color: Gray

Tack Free time: 30 minutes

Curing time: 7 – 21 days

Expansion rate: 3 – 5 times

Application temperature: 40° F – 104° F (5° C – 40° C)

In-Service Temperature: -13° F – 176° F (-25° C – 80°

C) Storage Temperature: 50° F – 95° F (10° C – 35° C)

Packaging: 310 ml/Tube, 25/CTN;

600 ml/Sausage, 20/CTN; 1 gal/pail & 5 gal/pail

Shelf Life: 24 months

Performance: 50+ years HOAC tested