Firestop Putty – MF012

MF012 – Firestop Putty – Technical Data Sheet

FM Approval Certificate of Compliance

UL Approval Certificate of Compliance

FM012 Firestop Putty is an industry leading elastomeric paste, with fast reacting intumescent properties, designed to seal gaps around through- penetrations and block the passage of flame, toxic fumes and smoke. FM012 Firestop Putty’s Listed designs offer exceptional performance and use less product, making it more cost effective than other traditional firestop

putties.

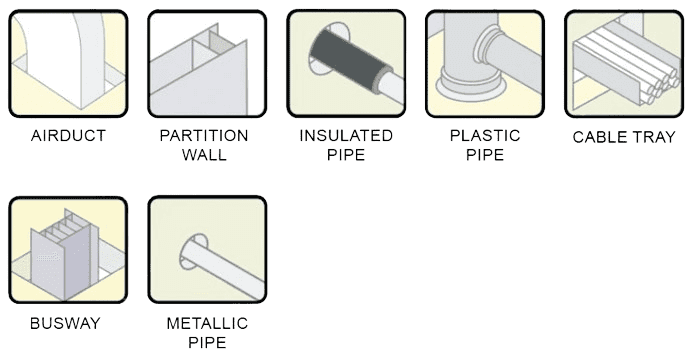

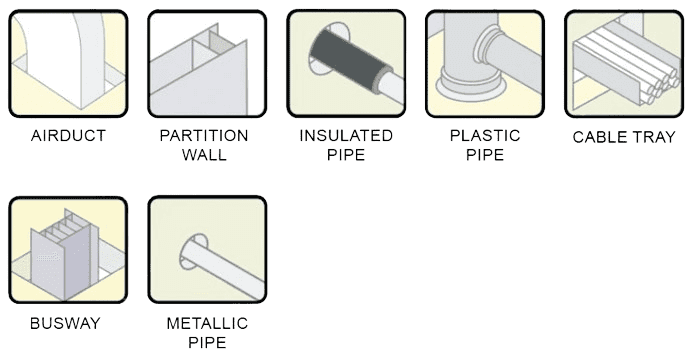

FM012 Firestop Putty is used to protect penetrations such as cable bundles, conduits, metallic pipes, plastic pipes, busways and air ducts with up to a 3-hour fire resistance rating.

FM012 is highly intumescent, offers rapid expansion and high volume char, has excellent elasticity, is easy to install and will not sag in vertical applications. Completely halogen and asbestos free, it does not contain organic solvents.

Meets the intent of LEED® VOC environmental air quality requirements.

- Ensure application area is clean and free of oil, loose dirt, rust or scale and is dry and frost free.

- Install the correct depth and compression of forming material, if required, as detailed within the applicable Listed system. Allow for sufficient depth of fill material.

- Using a caulking gun, trowel or putty knife, apply FM012 into the seams, gaps or voids between the penetrant and edge of annular space.

- Tool the sealant surface smooth using a putty knife dipped in water, making complete contact with substrates to ensure an airtight/smoke tight seal.

- Clean application tools with water.

- FM012 firestop putty cures by water evaporation. It is not recommended for use in a wet environment.

Specific Density: Approx. 11.50

Color: Red

VOC: 11.50 g/L

Curing Time: 7-14 days

Application Temp: 40° F – 104° F (5° C – 40° C)

In-Service Temp: -13° F – 176° F (-25° C – 80° C) Storage

Temp: 50° F – 95° F (10° – 35° C)

Shelf life: 24 months

Package: 310 ml/Tube; 25 Tubes/CTN;600 ml/Sausage, 20/

CTN 5Kgs/Pail, 20Kgs/Pail

Performance: 50+ years HOAC tested

Firestop Putty – MF012

MF012 – Firestop Putty – Technical Data Sheet

FM Approval Certificate of Compliance

UL Approval Certificate of Compliance

FM012 Firestop Putty is an industry leading elastomeric paste, with fast reacting intumescent properties, designed to seal gaps around through- penetrations and block the passage of flame, toxic fumes and smoke. FM012 Firestop Putty’s Listed designs offer exceptional performance and use less product, making it more cost effective than other traditional firestop

putties.

FM012 Firestop Putty is used to protect penetrations such as cable bundles, conduits, metallic pipes, plastic pipes, busways and air ducts with up to a 3-hour fire resistance rating.

FM012 is highly intumescent, offers rapid expansion and high volume char, has excellent elasticity, is easy to install and will not sag in vertical applications. Completely halogen and asbestos free, it does not contain organic solvents.

Meets the intent of LEED® VOC environmental air quality requirements.

- Ensure application area is clean and free of oil, loose dirt, rust or scale and is dry and frost free.

- Install the correct depth and compression of forming material, if required, as detailed within the applicable Listed system. Allow for sufficient depth of fill material.

- Using a caulking gun, trowel or putty knife, apply FM012 into the seams, gaps or voids between the penetrant and edge of annular space.

- Tool the sealant surface smooth using a putty knife dipped in water, making complete contact with substrates to ensure an airtight/smoke tight seal.

- Clean application tools with water.

- FM012 firestop putty cures by water evaporation. It is not recommended for use in a wet environment.

Specific Density: Approx. 11.50

Color: Red

VOC: 11.50 g/L

Curing Time: 7-14 days

Application Temp: 40° F – 104° F (5° C – 40° C)

In-Service Temp: -13° F – 176° F (-25° C – 80° C) Storage

Temp: 50° F – 95° F (10° – 35° C)

Shelf life: 24 months

Package: 310 ml/Tube; 25 Tubes/CTN;600 ml/Sausage, 20/

CTN 5Kgs/Pail, 20Kgs/Pail

Performance: 50+ years HOAC tested