Mortar – CFS01

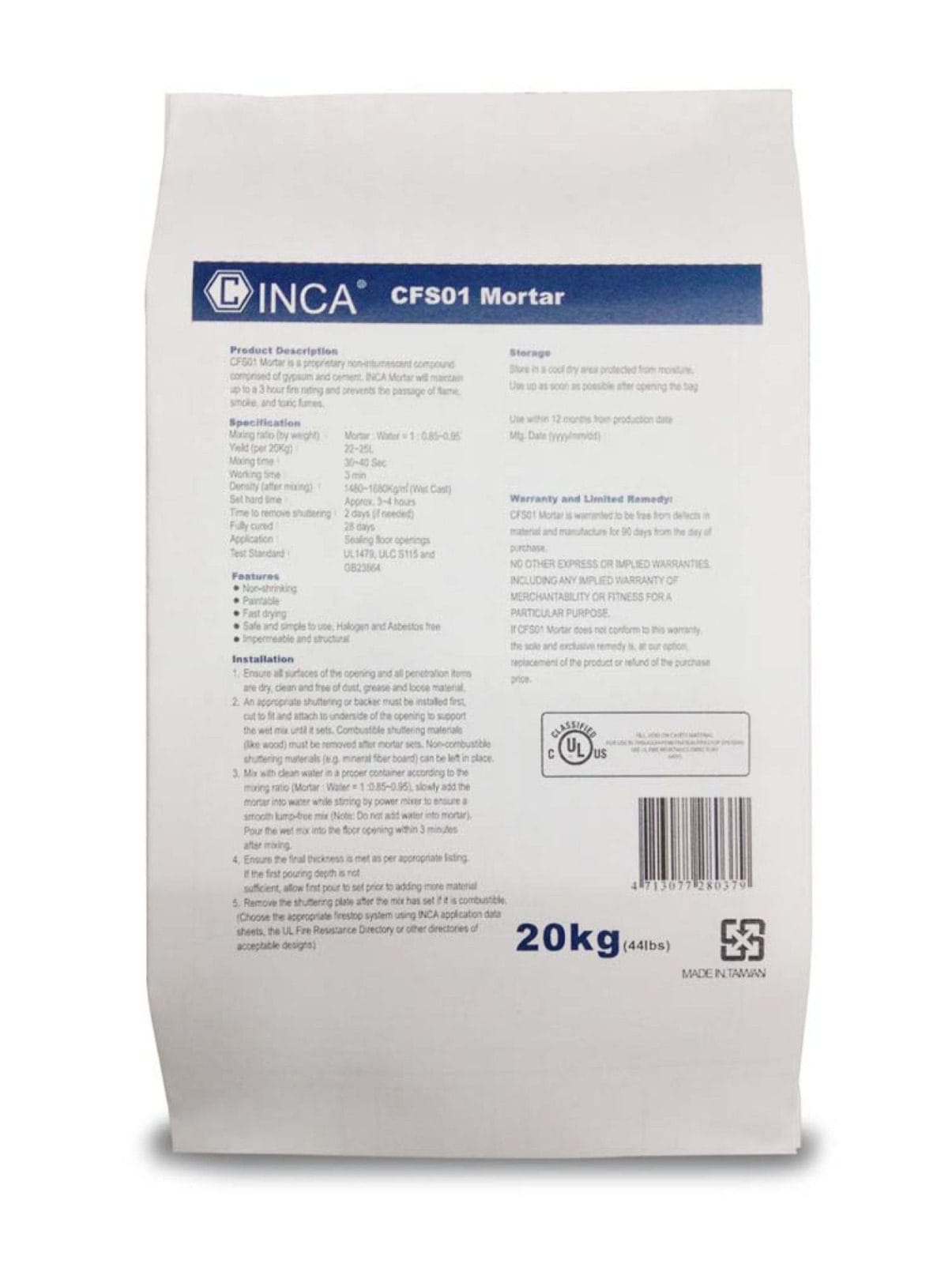

CFS01 Mortar is an industry leading non-intumescent firestop mortar comprised of a proprietary blend of gypsum and cement. CFS01 Mortar is designed with installation convenience in mind. Our “Variable Viscosity” technology allows the installer to add less water for a thicker consistency or more water for a thinner consistency, depending on the application needs. CFS01 Mortar provides up to 3 hours fire rating to prevent passage of flame, smoke, and toxic fumes.

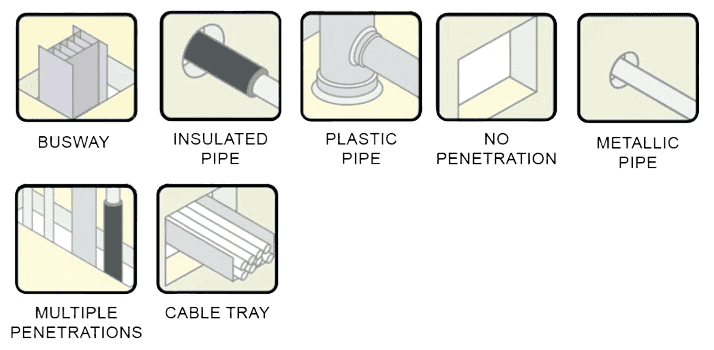

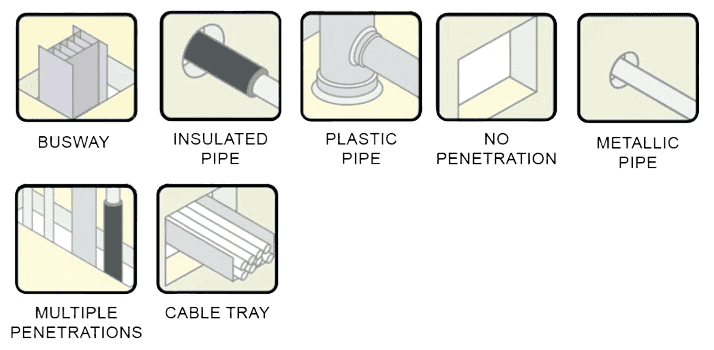

Per its mix ratios, CFS01 Mortar is the most cost effective mortar solution on the market. It is typically used to seal mechanical and electrical service penetrations, blank openings and other large annular spaces in fire-resistance rated wall and floor assemblies with ratings up to 3 hour assembly testing. CFS01 Mortar is non-shrinking, paintable, fast drying, safe, simple to use, halogen and asbestos free. Water and gas impermeable, it offers excellent structural strength while still being re-penetrable and repairable.

Meets the intent of LEED® VOC environmental air quality requirements

- Clean surfaces of the opening and all penetration items to ensure adhesion.Opening must be dry, frost free and void of any grease and dust.

- An appropriate backer must be installed first, as per Listed system, cut to fit below the opening to support the mix until it cures.

- Mix with clean potable water in a proper container according to the mix- ing ratio (1 parts mortar mix: 0.85 – 0.95 part water), slowly adding the mortar into water while stirring by power mixer to ensure a smooth lump- free mix (Note: Do not add water into mortar). Mix well for 30-40 seconds. The wet mixture is best poured into the floor opening within 3 minutes after mixing.

- Pour the wet mix into the opening, allowing for the proper depth of fill materials. If the first pouring depth is not sufficient, add more wet mix after themortar is set.

- Remove the backer after the mix has set if it is combustible. Noncom bustible backers may remain in place.

- Clean all tools and mixing containers with water immediately after using

Mixing ratio by weight:(1 part mortar mix:0.85 – 0.95 part water)

Yield (per 20Kg): 22-25L (1345 in3 -1525 in³)

Density(after mixing):1480-1680kg/m3(Wet cast)

Drying time: 3 – 4 hours

Time to remove backer (if required):2 days

Fully cured: 28 days

Application Temperature Range: 40° F – 104° F(5° C – 40° C)

In-Service Temperature:-13° F – 176° F(-25° C – 80° C)

Packing: 20Kgs/Bag

Shelf Life: 3 years, when stored indoors in dryconditions in original

unopened packaging

Mortar – CFS01

CFS01 Mortar is an industry leading non-intumescent firestop mortar comprised of a proprietary blend of gypsum and cement. CFS01 Mortar is designed with installation convenience in mind. Our “Variable Viscosity” technology allows the installer to add less water for a thicker consistency or more water for a thinner consistency, depending on the application needs. CFS01 Mortar provides up to 3 hours fire rating to prevent passage of flame, smoke, and toxic fumes.

Per its mix ratios, CFS01 Mortar is the most cost effective mortar solution on the market. It is typically used to seal mechanical and electrical service penetrations, blank openings and other large annular spaces in fire-resistance rated wall and floor assemblies with ratings up to 3 hour assembly testing. CFS01 Mortar is non-shrinking, paintable, fast drying, safe, simple to use, halogen and asbestos free. Water and gas impermeable, it offers excellent structural strength while still being re-penetrable and repairable.

Meets the intent of LEED® VOC environmental air quality requirements

- Clean surfaces of the opening and all penetration items to ensure adhesion.Opening must be dry, frost free and void of any grease and dust.

- An appropriate backer must be installed first, as per Listed system, cut to fit below the opening to support the mix until it cures.

- Mix with clean potable water in a proper container according to the mix- ing ratio (1 parts mortar mix: 0.85 – 0.95 part water), slowly adding the mortar into water while stirring by power mixer to ensure a smooth lump- free mix (Note: Do not add water into mortar). Mix well for 30-40 seconds. The wet mixture is best poured into the floor opening within 3 minutes after mixing.

- Pour the wet mix into the opening, allowing for the proper depth of fill materials. If the first pouring depth is not sufficient, add more wet mix after themortar is set.

- Remove the backer after the mix has set if it is combustible. Noncom bustible backers may remain in place.

- Clean all tools and mixing containers with water immediately after using

Mixing ratio by weight:(1 part mortar mix:0.85 – 0.95 part water)

Yield (per 20Kg): 22-25L (1345 in3 -1525 in³)

Density(after mixing):1480-1680kg/m3(Wet cast)

Drying time: 3 – 4 hours

Time to remove backer (if required):2 days

Fully cured: 28 days

Application Temperature Range: 40° F – 104° F(5° C – 40° C)

In-Service Temperature:-13° F – 176° F(-25° C – 80° C)

Packing: 20Kgs/Bag

Shelf Life: 3 years, when stored indoors in dryconditions in original

unopened packaging