Fire Barrier Foam – US150

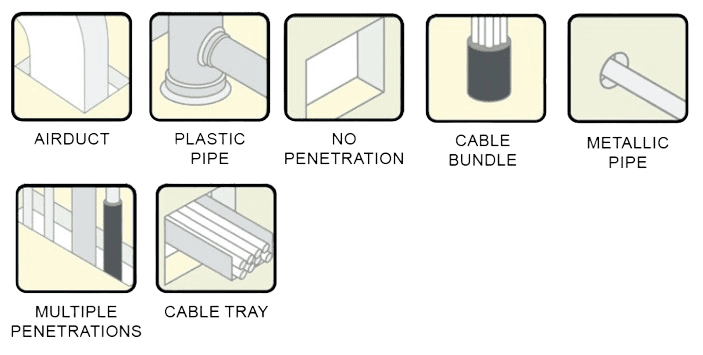

Industry leading Firestop Technology, US150 Fire Barrier Foam is a two component high density foam which, when mixed, forms a rigid-density fire retardant foam. US150 Fire Barrier Foam is designed for large openings containing single or multiple penetra-tions.

US150 Fire Barrier Foam’s fast expansion technology quickly fills voids, and conforms to irregular shapes and sizes, offering excel-lent protection from fire, heat transfer, smoke and gases.Repairable and re-penetrable, US150’s rigid structure is easy to drill using common hole saws, ideal for irregular shaped openings that will require future penetrations.US150 Fire Barrier Foam is low VOC, halogen and asbestos free, durable and maintenance free.

Meets the intent of LEED® VOC environmental air quality

- Areas to be protected must be clean and free of oil, loose dirt, rust or scale. Installation temperatures must be between 50° and 90° F (10°C and 32° C).

- Calculate amount of material required, based on the fact that a 20 Kg kit yields 60,000 cm3.

- US150 is supplied as two part components (Parts A & B). Settling and separation during storage is expected, therefore both components must be stirred with a clean paddle or suitable power mixer prior to use.

- Using a scale, weigh out and mix parts of US150A and US150B at a ratio of 7 – 3. Mixing may be accomplished using a paddle mixer or other suitable power mixer in a container or by the use of automatic mixing and dispensing equipment. If paddle mixing is used, mix aggressively for 30 seconds.

- Immediately pour mixed foam into the penetration. Product rises and cures in1- 5 minutes depending on temperature.

- Mechanical mixing and dispensing is recommended for large volume applications

US150 A Color: Black Packing: 14Kg/Pail

US150 B Color: Yellow Packing: 6Kg/Pail

Foaming time: 1 – 5 min.

Optimum foaming temp: 50° F -90° F (10° C – 32° C)

Curing Time: 24 hours

Volume expansion: 2.5 – 4 times

LO.I.: 732

Storage temp: 50° F – 77° F (15°C – 25°C)

In-Service temp: -13° F – 176° F (-25° C – 80° C)

Shelf life: 12 months

Intumescent expansion rate: 2-5 times

Mix ratio A:B 7-3 by weight

Yield per kit: 60,000 cm (depending on ambient conditions)

Performance: 50+ years HOAC tested

Fire Barrier Foam – US150

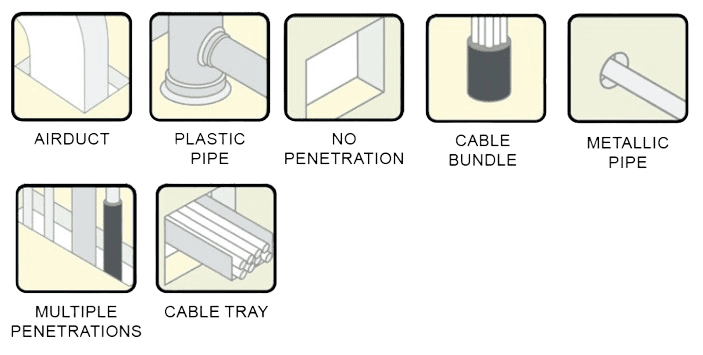

Industry leading Firestop Technology, US150 Fire Barrier Foam is a two component high density foam which, when mixed, forms a rigid-density fire retardant foam. US150 Fire Barrier Foam is designed for large openings containing single or multiple penetra-tions.

US150 Fire Barrier Foam’s fast expansion technology quickly fills voids, and conforms to irregular shapes and sizes, offering excel-lent protection from fire, heat transfer, smoke and gases.Repairable and re-penetrable, US150’s rigid structure is easy to drill using common hole saws, ideal for irregular shaped openings that will require future penetrations.US150 Fire Barrier Foam is low VOC, halogen and asbestos free, durable and maintenance free.

Meets the intent of LEED® VOC environmental air quality

- Areas to be protected must be clean and free of oil, loose dirt, rust or scale. Installation temperatures must be between 50° and 90° F (10°C and 32° C).

- Calculate amount of material required, based on the fact that a 20 Kg kit yields 60,000 cm3.

- US150 is supplied as two part components (Parts A & B). Settling and separation during storage is expected, therefore both components must be stirred with a clean paddle or suitable power mixer prior to use.

- Using a scale, weigh out and mix parts of US150A and US150B at a ratio of 7 – 3. Mixing may be accomplished using a paddle mixer or other suitable power mixer in a container or by the use of automatic mixing and dispensing equipment. If paddle mixing is used, mix aggressively for 30 seconds.

- Immediately pour mixed foam into the penetration. Product rises and cures in1- 5 minutes depending on temperature.

- Mechanical mixing and dispensing is recommended for large volume applications

US150 A Color: Black Packing: 14Kg/Pail

US150 B Color: Yellow Packing: 6Kg/Pail

Foaming time: 1 – 5 min.

Optimum foaming temp: 50° F -90° F (10° C – 32° C)

Curing Time: 24 hours

Volume expansion: 2.5 – 4 times

LO.I.: 732

Storage temp: 50° F – 77° F (15°C – 25°C)

In-Service temp: -13° F – 176° F (-25° C – 80° C)

Shelf life: 12 months

Intumescent expansion rate: 2-5 times

Mix ratio A:B 7-3 by weight

Yield per kit: 60,000 cm (depending on ambient conditions)

Performance: 50+ years HOAC tested