Fireproof Paint for Structural Steel – DC7120

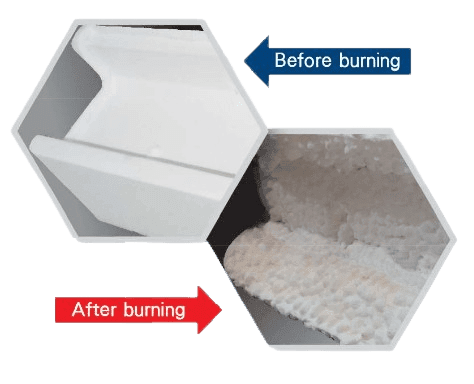

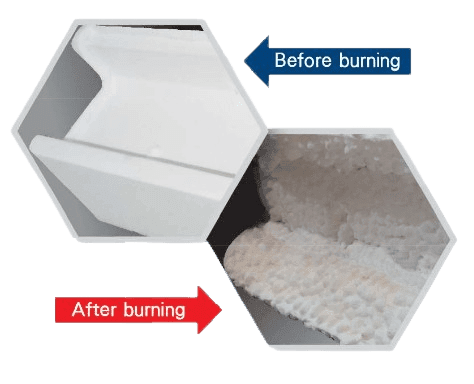

DC7120 is a single-component water-based intumescent coating specially designed to increase the fire resistance of structural steel. Upon exposure to flame or heat, it immediately foams and intumesces to form a thermal barrier layer that provides effective insulation to protect the steel sections from fire and heat.

- Surface Preparation:

- Clean steel of rust, grease, and contaminants.

- Abrasive blast clean (SSPC-SP10 / SIS-Sa 2½).

- Apply over compatible anti-corrosive primer (e.g., epoxy zinc phosphate, 50–75 μm DFT).

- Ensure primer is fully cured and clean.

- Site Conditions:

- Apply above 5°C (preferably >10°C); steel temp ≥ 3°C above dew point.

- Relative humidity < 80%; ensure good ventilation.

- Protect coating from moisture, rain, and condensation.

- Application Procedure:

- Mix thoroughly; thin with water max 3% if needed.

- Use high-pressure airless spray (min 3000 psi, tip 0.015–0.025 in).

- Spray 30 cm from surface, overlapping 30–40%.

- Max coat thickness: 700 µm (wet).

- Recoat after 6–12 hours; final DFT per spec.

- Measure thickness with electronic gauge; avoid sagging.

- Allow 24h drying before topcoat; protect from moisture.

- Topcoat (Optional):

- Apply only after full curing.

- Required in unconditioned interiors; optional for conditioned interiors.

- Cleanup & Storage:

- Clean tools with water immediately.

- Store sealed containers indoors at 5–35°C.

- Shelf life: 24 months.

Certifire Listed with Warringtonfire in accordance with BS476 Part 21

Fire rating up to 2 hours

Water-borne and environmentally friendly

Smooth and architecturally pleasing finish

Very low odour

Fast drying and rapid recoating properties

Excellent durability

DC7120 Intumescent Coating for Interior Structural Steel

DC7120 is a single-component water-based intumescent coating specially designed to increase the fire resistance of structural steel. Upon exposure to flame or heat, it immediately foams and intumesces to form a thermal barrier layer that provides effective insulation to protect the steel sections from fire and heat.

- Surface Preparation:

- Clean steel of rust, grease, and contaminants.

- Abrasive blast clean (SSPC-SP10 / SIS-Sa 2½).

- Apply over compatible anti-corrosive primer (e.g., epoxy zinc phosphate, 50–75 μm DFT).

- Ensure primer is fully cured and clean.

- Site Conditions:

- Apply above 5°C (preferably >10°C); steel temp ≥ 3°C above dew point.

- Relative humidity < 80%; ensure good ventilation.

- Protect coating from moisture, rain, and condensation.

- Application Procedure:

- Mix thoroughly; thin with water max 3% if needed.

- Use high-pressure airless spray (min 3000 psi, tip 0.015–0.025 in).

- Spray 30 cm from surface, overlapping 30–40%.

- Max coat thickness: 700 µm (wet).

- Recoat after 6–12 hours; final DFT per spec.

- Measure thickness with electronic gauge; avoid sagging.

- Allow 24h drying before topcoat; protect from moisture.

- Topcoat (Optional):

- Apply only after full curing.

- Required in unconditioned interiors; optional for conditioned interiors.

- Cleanup & Storage:

- Clean tools with water immediately.

- Store sealed containers indoors at 5–35°C.

- Shelf life: 24 months.

Certifire Listed with Warringtonfire in accordance with BS476 Part 21

Fire rating up to 2 hours

Water-borne and environmentally friendly

Smooth and architecturally pleasing finish

Very low odour

Fast drying and rapid recoating properties

Excellent durability