Fireproof Paint – DC333

FM Approval Certificate of Compliance

INTERTEK Approval Certificate of Compliance

UL Approval Certificate of Compliance

COMING SOON

DC333 Fireproof Paint is produced by a new state of art fire retardant system using proprietary leading edge intumescent fire retardancy and fire resistance.

DC333 Fireproof Paint has been highly tested and has passed countless tests from nationally certified labs and testing facilities.

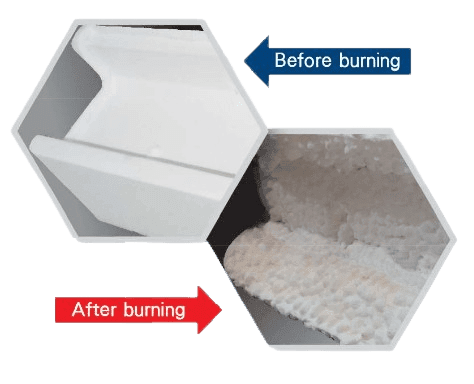

When exposed to high temperatures or direct flame, it expands, then caramelizing forming a “char barrier” that lifts off the surface, or on materials. In doing so, DC333 Fireproof Paint offers an effective and durable barrier that cuts off the fuel source that fire needs to develop and reduces smoke dramatically.

DC333 is best applied with an airless sprayer to achieve a more consi D stent mil thickness. In challenging areas where an airless sprayer is not pracÅcal, DC333 can be applied by brush or roller.

· Brush: Use top quality polyester/nylon blend brushes, such as those supplied by Purdy, Wooster, or equivalent

· Roller: Use a 3/8” polyester blend nap roller, which will generally work well when applying DC333

DC333 VISCOSITY: DC333 is a variable viscosity coaÅng. When you open DC333 the unmixed viscosity will be approximately 30,000 – 35,000 CPS. A!er mixing for five minutes the viscosity will drop 15,000 CPS to approximately 20,000 CPS. If viscosity is sÅll too high you can add 8 ounce of water per 5 gallon pail and mix to reduce the viscosity by 4000 – 5000 CPS.

– Coverage: DC333 MUST BE THOROUGHLY MIXED FOR 5 MINUTES PRIOR TO APPLICATION WITH A MECHANICAL MIXER Check appropriate test report or ESR for required wet film thickness (WFT) and gallon per square coverage. For example, if the wet film thickness (WFT) required is 18 mils, the coverage will be 89 sq. !. per gallon.

– Curing: Fans should be used to circulate air for the first 24 hours of curing. Do not blow air directly on coating.

Water Base

300 sq. ft. per Gallon as Class A

Non-Toxic

Hypoallergenic

Non-Carcinogenic

Passed Strict EPA – V.O.C. and AQMD

Spray, Roll, or Brush

Compa!ble with any paintable surface

Fireproof Paint – DC333

FM Approval Certificate of Compliance

INTERTEK Approval Certificate of Compliance

UL Approval Certificate of Compliance

COMING SOON

DC333 Fireproof Paint is produced by a new state of art fire retardant system using proprietary leading edge intumescent fire retardancy and fire resistance.

DC333 Fireproof Paint has been highly tested and has passed countless tests from nationally certified labs and testing facilities.

When exposed to high temperatures or direct flame, it expands, then caramelizing forming a “char barrier” that lifts off the surface, or on materials. In doing so, DC333 Fireproof Paint offers an effective and durable barrier that cuts off the fuel source that fire needs to develop and reduces smoke dramatically.

DC333 is best applied with an airless sprayer to achieve a more consi D stent mil thickness. In challenging areas where an airless sprayer is not pracÅcal, DC333 can be applied by brush or roller.

· Brush: Use top quality polyester/nylon blend brushes, such as those supplied by Purdy, Wooster, or equivalent

· Roller: Use a 3/8” polyester blend nap roller, which will generally work well when applying DC333

DC333 VISCOSITY: DC333 is a variable viscosity coaÅng. When you open DC333 the unmixed viscosity will be approximately 30,000 – 35,000 CPS. A!er mixing for five minutes the viscosity will drop 15,000 CPS to approximately 20,000 CPS. If viscosity is sÅll too high you can add 8 ounce of water per 5 gallon pail and mix to reduce the viscosity by 4000 – 5000 CPS.

– Coverage: DC333 MUST BE THOROUGHLY MIXED FOR 5 MINUTES PRIOR TO APPLICATION WITH A MECHANICAL MIXER Check appropriate test report or ESR for required wet film thickness (WFT) and gallon per square coverage. For example, if the wet film thickness (WFT) required is 18 mils, the coverage will be 89 sq. !. per gallon.

– Curing: Fans should be used to circulate air for the first 24 hours of curing. Do not blow air directly on coating.

Water Base

300 sq. ft. per Gallon as Class A

Non-Toxic

Hypoallergenic

Non-Carcinogenic

Passed Strict EPA – V.O.C. and AQMD

Spray, Roll, or Brush

Compa!ble with any paintable surface

DC7120 Intumescent Coating for Interior Structural Steel

FM Approval Certificate of Compliance

INTERTEK Approval Certificate of Compliance

UL Approval Certificate of Compliance

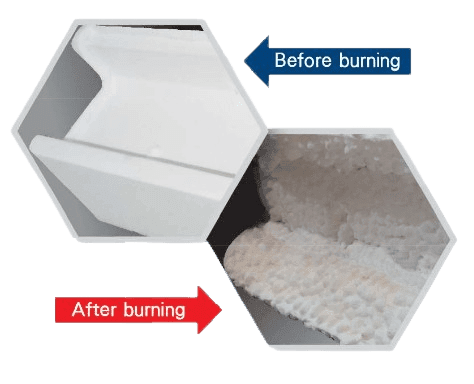

DC7120 is a single-component water-based intumescent coating specially designed to increase the fire resistance of structural steel. Upon exposure to flame or heat, it immediately foams and intumesces to form a thermal barrier layer that provides effective insulation to protect the steel sections from fire and heat.

- Surface Preparation:

- Clean steel of rust, grease, and contaminants.

- Abrasive blast clean (SSPC-SP10 / SIS-Sa 2½).

- Apply over compatible anti-corrosive primer (e.g., epoxy zinc phosphate, 50–75 μm DFT).

- Ensure primer is fully cured and clean.

- Site Conditions:

- Apply above 5°C (preferably >10°C); steel temp ≥ 3°C above dew point.

- Relative humidity < 80%; ensure good ventilation.

- Protect coating from moisture, rain, and condensation.

- Application Procedure:

- Mix thoroughly; thin with water max 3% if needed.

- Use high-pressure airless spray (min 3000 psi, tip 0.015–0.025 in).

- Spray 30 cm from surface, overlapping 30–40%.

- Max coat thickness: 700 µm (wet).

- Recoat after 6–12 hours; final DFT per spec.

- Measure thickness with electronic gauge; avoid sagging.

- Allow 24h drying before topcoat; protect from moisture.

- Topcoat (Optional):

- Apply only after full curing.

- Required in unconditioned interiors; optional for conditioned interiors.

- Cleanup & Storage:

- Clean tools with water immediately.

- Store sealed containers indoors at 5–35°C.

- Shelf life: 24 months.

Certifire Listed with Warringtonfire in accordance with BS476 Part 21

Fire rating up to 2 hours

Water-borne and environmentally friendly

Smooth and architecturally pleasing finish

Very low odour

Fast drying and rapid recoating properties

Excellent durability

DC7120 Intumescent Coating for Interior Structural Steel

FM Approval Certificate of Compliance

INTERTEK Approval Certificate of Compliance

UL Approval Certificate of Compliance

DC7120 is a single-component water-based intumescent coating specially designed to increase the fire resistance of structural steel. Upon exposure to flame or heat, it immediately foams and intumesces to form a thermal barrier layer that provides effective insulation to protect the steel sections from fire and heat.

- Surface Preparation:

- Clean steel of rust, grease, and contaminants.

- Abrasive blast clean (SSPC-SP10 / SIS-Sa 2½).

- Apply over compatible anti-corrosive primer (e.g., epoxy zinc phosphate, 50–75 μm DFT).

- Ensure primer is fully cured and clean.

- Site Conditions:

- Apply above 5°C (preferably >10°C); steel temp ≥ 3°C above dew point.

- Relative humidity < 80%; ensure good ventilation.

- Protect coating from moisture, rain, and condensation.

- Application Procedure:

- Mix thoroughly; thin with water max 3% if needed.

- Use high-pressure airless spray (min 3000 psi, tip 0.015–0.025 in).

- Spray 30 cm from surface, overlapping 30–40%.

- Max coat thickness: 700 µm (wet).

- Recoat after 6–12 hours; final DFT per spec.

- Measure thickness with electronic gauge; avoid sagging.

- Allow 24h drying before topcoat; protect from moisture.

- Topcoat (Optional):

- Apply only after full curing.

- Required in unconditioned interiors; optional for conditioned interiors.

- Cleanup & Storage:

- Clean tools with water immediately.

- Store sealed containers indoors at 5–35°C.

- Shelf life: 24 months.

Certifire Listed with Warringtonfire in accordance with BS476 Part 21

Fire rating up to 2 hours

Water-borne and environmentally friendly

Smooth and architecturally pleasing finish

Very low odour

Fast drying and rapid recoating properties

Excellent durability