Firestop Sheet – FP-02

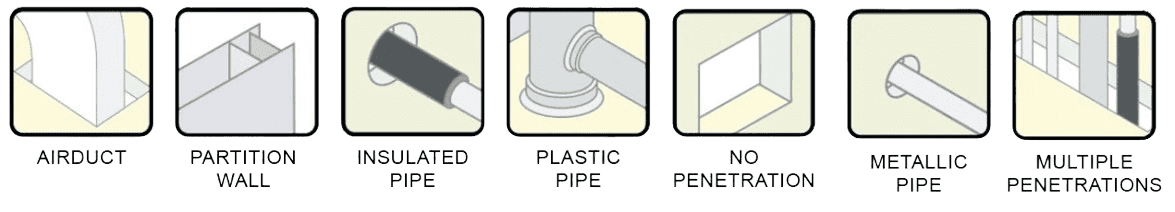

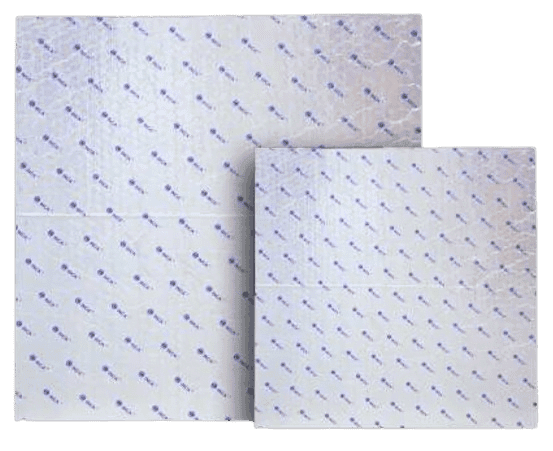

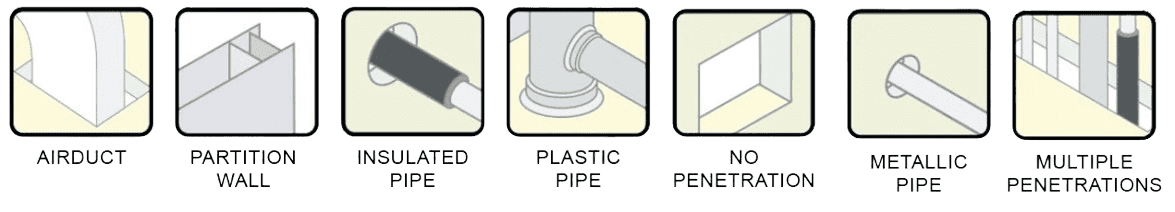

FP-02 is an industry leading Firestop Sheet fabricated by bonding proprietary intumescent materials to a metal sheet. FP02 securely blocks flame and is designed to seal large penetrations through fire-rated walls and floors. It is also used for shielding cable trays, conduit, HVAC and vital process equipment from radiant heat, flame spread and smoke.

FP-02 Firestop Sheet steel backer provides structure to the assembly making a safe firestop solution for floor openings.

Easily re-penetrable and repairable with a common hole saw, it is the most cost effective solutions for large openings on

the market today.

FP-02 Firestop Sheet is easily trimmed to different sizes to fit any installation or large openings and works with nearly all construction materials. It is halogen and asbestos free, is very stable and maintenance free.

Meets the intent of LEED® VOC environmental air quality requirements

- Ensure application area is clean and free of oil, loose dirt, rust or scale.

- When max opening dimensions exceed 20 in. (508mm) in both width and length, two minimum 2 x 2 in. (51 by 51 mm) by No.10 gauge galvanized steel angles shall be installed within the longest dimension of the opening, with one angle flush with both top or bottom of floor or both surfaces of wall. These angles provide a framing member for intermediate securement of the firestop sheet.

- FP-02 Firestop Sheet is to be installed to lap a minimum of 2 in. (51 mm) on all sides of the through opening and with the aluminum foil facing against the surface of the floor (galvanized steel plate side outwards).

- Apply a min 3/8 in. (10 mm) thickness of INSS1440 around the periphery of each firestop sheet prior to securing it to the floor or wall. In addi- tion, min 3/8 in. (10 mm) bead of sealant applied at the periphery of the through penetrant firestop sheet interface on both sides of the floor or wall.

- FP-02 Firestop Sheet is to be secured to the top surface of floor using min 3/16 in. diam by 1-1/2 in. (5 mm by 38 mm) long steel expansion bolts in conjunction with min 1-1/4 in. (32 mm) diam steel fender washers. Max spacing of fasteners not to exceed 6 in. (152 mm) OC.

- All wall openings require installation of FP-02 Firestop Sheet and putty/ sealant on both sides of the wall.

Size: 90cm x 90cm

Thickness: 7.7 ± 1.3 mm

Weight (per sheet): 11 Kgs

Expansion Rate: 5 – 10 Times

In-Service Temp: -13° F – 176° F (-25 °C – 80° C)

Packaging: Single sheet

Firestop Sheet – FP-02

FP-02 is an industry leading Firestop Sheet fabricated by bonding proprietary intumescent materials to a metal sheet. FP02 securely blocks flame and is designed to seal large penetrations through fire-rated walls and floors. It is also used for shielding cable trays, conduit, HVAC and vital process equipment from radiant heat, flame spread and smoke.

FP-02 Firestop Sheet steel backer provides structure to the assembly making a safe firestop solution for floor openings.

Easily re-penetrable and repairable with a common hole saw, it is the most cost effective solutions for large openings on

the market today.

FP-02 Firestop Sheet is easily trimmed to different sizes to fit any installation or large openings and works with nearly all construction materials. It is halogen and asbestos free, is very stable and maintenance free.

Meets the intent of LEED® VOC environmental air quality requirements

- Ensure application area is clean and free of oil, loose dirt, rust or scale.

- When max opening dimensions exceed 20 in. (508mm) in both width and length, two minimum 2 x 2 in. (51 by 51 mm) by No.10 gauge galvanized steel angles shall be installed within the longest dimension of the opening, with one angle flush with both top or bottom of floor or both surfaces of wall. These angles provide a framing member for intermediate securement of the firestop sheet.

- FP-02 Firestop Sheet is to be installed to lap a minimum of 2 in. (51 mm) on all sides of the through opening and with the aluminum foil facing against the surface of the floor (galvanized steel plate side outwards).

- Apply a min 3/8 in. (10 mm) thickness of INSS1440 around the periphery of each firestop sheet prior to securing it to the floor or wall. In addi- tion, min 3/8 in. (10 mm) bead of sealant applied at the periphery of the through penetrant firestop sheet interface on both sides of the floor or wall.

- FP-02 Firestop Sheet is to be secured to the top surface of floor using min 3/16 in. diam by 1-1/2 in. (5 mm by 38 mm) long steel expansion bolts in conjunction with min 1-1/4 in. (32 mm) diam steel fender washers. Max spacing of fasteners not to exceed 6 in. (152 mm) OC.

- All wall openings require installation of FP-02 Firestop Sheet and putty/ sealant on both sides of the wall.

Size: 90cm x 90cm

Thickness: 7.7 ± 1.3 mm

Weight (per sheet): 11 Kgs

Expansion Rate: 5 – 10 Times

In-Service Temp: -13° F – 176° F (-25 °C – 80° C)

Packaging: Single sheet