Intumescent Strip – INFS0812 / INFS0822

Intumescent Strip INFS0812 / INFS0822 – Technical Data Sheet

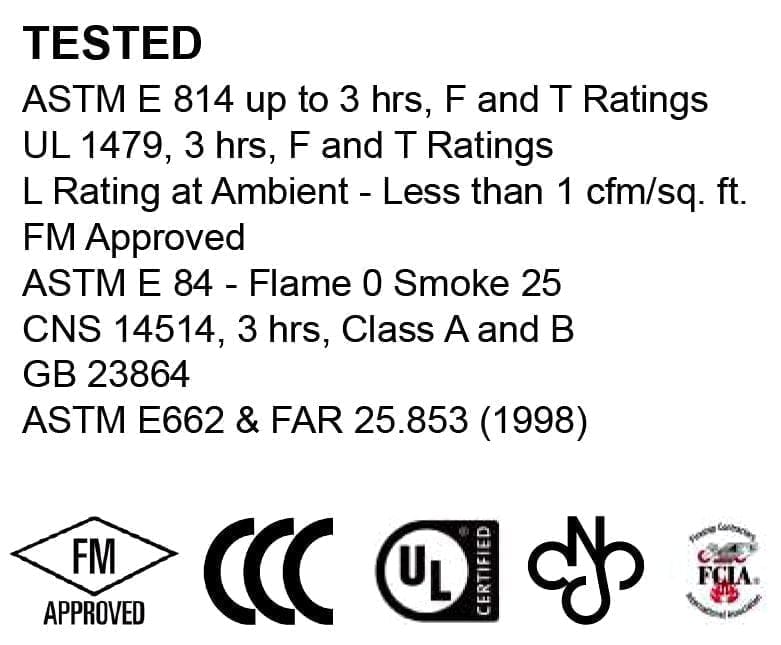

FM Approval Certificate of Compliance

INTERTEK Approval Certificate of Compliance

UL Approval Certificate of Compliance

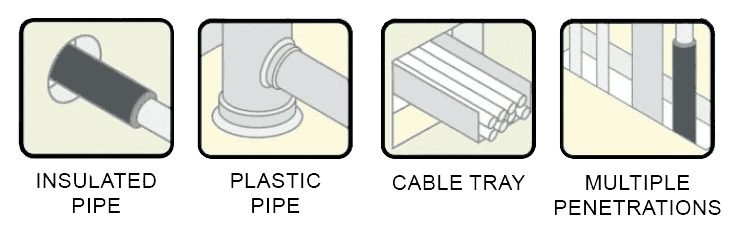

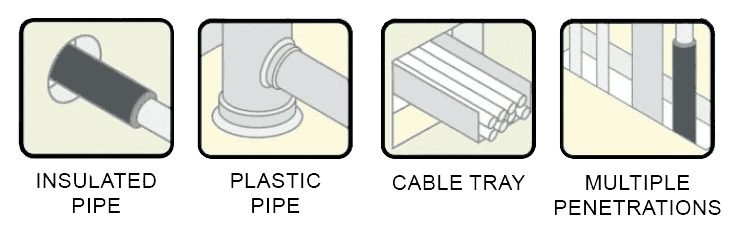

INFS0812 Intumescent Strips are quickly and easily installed providing a convenient solution for firestop contractors. Providing high expansion rate and volume means that the INFS0812 design requires less strips to seal the openings, making it more cost effective than other traditional firestop intumescent strips.

INFS0812 Intumescent Strips expand when heated and maintain a tight seal. When used with combustible penetrants such as plastic pipe, INFS0812 blocks the spread of fire, smoke, toxic gases, even as the penetrant is consumed by fire.

INFS0812 Intumescent Strips are also used in conjunction with our SSCI Firestop Collar to tightly seal any opening that is

created as a combustible item is consumed by fire.

Meets the intent of LEED® VOC environmental air quality requirements

- Ensure application area is clean and free of oil, loose dirt, rust or scale.

- Install min 4pcf (64 kg/m3) mineral wool batt insulation firmly packed into opening as a permanent form, as detailed in Listed system.

- The required number of layers of wrap strip are to be individually and tightly wrapped around each nonmetallic through penetrant and secured together by means of ALfoil tape.

- Wrap strip shall be butted against floor bottom or both surfaces of wall, or as detailed in listed assembly.

- Seal penetration against smoke using, for instance, INSS1440 or INSS2460 sealants is encouraged.

INFS0812: 5mm x 60mm x 2M

INFS0822: 5mm x 60mm x 10M

Color: Black

Expansion Rate: ≥ 20 times

L.O.I: ≥ 40

In-Service Temperature: -13° F – 176° F (-25° C – 80° C)

Storage Temperature: 50° F – 95° F (10° C – 35° C)

Environmental Exposure Tests

Accelerated aging: Passed

High Humidity: Passed

Performance: 50+ years HOAC Tested

Intumescent Strip – INFS0812 / INFS0822

Intumescent Strip INFS0812 / INFS0822 – Technical Data Sheet

FM Approval Certificate of Compliance

INTERTEK Approval Certificate of Compliance

UL Approval Certificate of Compliance

INFS0812 Intumescent Strips are quickly and easily installed providing a convenient solution for firestop contractors. Providing high expansion rate and volume means that the INFS0812 design requires less strips to seal the openings, making it more cost effective than other traditional firestop intumescent strips.

INFS0812 Intumescent Strips expand when heated and maintain a tight seal. When used with combustible penetrants such as plastic pipe, INFS0812 blocks the spread of fire, smoke, toxic gases, even as the penetrant is consumed by fire.

INFS0812 Intumescent Strips are also used in conjunction with our SSCI Firestop Collar to tightly seal any opening that is

created as a combustible item is consumed by fire.

Meets the intent of LEED® VOC environmental air quality requirements

- Ensure application area is clean and free of oil, loose dirt, rust or scale.

- Install min 4pcf (64 kg/m3) mineral wool batt insulation firmly packed into opening as a permanent form, as detailed in Listed system.

- The required number of layers of wrap strip are to be individually and tightly wrapped around each nonmetallic through penetrant and secured together by means of ALfoil tape.

- Wrap strip shall be butted against floor bottom or both surfaces of wall, or as detailed in listed assembly.

- Seal penetration against smoke using, for instance, INSS1440 or INSS2460 sealants is encouraged.

INFS0812: 5mm x 60mm x 2M

INFS0822: 5mm x 60mm x 10M

Color: Black

Expansion Rate: ≥ 20 times

L.O.I: ≥ 40

In-Service Temperature: -13° F – 176° F (-25° C – 80° C)

Storage Temperature: 50° F – 95° F (10° C – 35° C)

Environmental Exposure Tests

Accelerated aging: Passed

High Humidity: Passed

Performance: 50+ years HOAC Tested